Discover the definitive Toyota Hiace Engine Belt Diagram guide that is tailored for modern car owners. In this guide, you'll explore detailed belt routing diagrams, learn the correct way for serpentine belt replacement and timing belt maintenance, and understand key components to keep your engine running smoothly.

How to Read Your Toyota Hiace Belt Diagram Correctly

Locating the Belt Layout

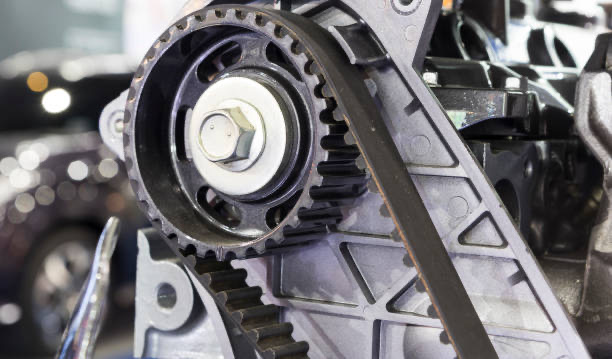

When you open your engine compartment, take a moment to locate the factory decal that illustrates the belt routing. This diagram not only highlights the path of the serpentine belt across vital components but also shows the precise location of the tensioner pulley and accessory pulleys. The diagram is your first tool to ensure that every component from the crankshaft to the alternator is correctly aligned, helping you avoid common mistakes during installation or replacement.

3 Critical Components in Belt Systems

Understanding the key elements of your engine belt system is crucial:

Drive Belt (V-Ribbed Belt):

Powers multiple engine accessories such as the alternator, AC compressor, and water pump.

Recommended replacement cycle:every 60,000 km to maintain optimal efficiency.

A clear diagram helps you verify the correct routing and ensure that each rib fits perfectly into the pulley grooves.

Timing Belt (If Equipped):

Synchronizes the crankshaft and camshaft, thereby keeping your engine's timing precise.

Should be replaced every 100,000 km to prevent engine damage.

Using the engine belt diagram ensures every notch and mark is followed accurately.

Tensioner Assembly:

Ensures that the belt maintains the right amount of tension at all times.

It is advisable to inspect the tensioner assembly every 30,000 km, as even a slight misalignment can lead to premature wear.

Step-by-Step Belt Replacement Guide

Tools You'll Need

Before starting the replacement process, gather the following tools to simplify your task:

A 14mm combination wrench

A belt tension gauge

A printed copy of your Toyota Hiace engine belt routing diagram

A torque wrench with a setting in the 35-50 Nm range

Installation Process

Follow these steps carefully to ensure that your new belt is installed correctly:

Release Belt Tension:

Begin by releasing the tension using the automatic adjuster. This step eases the removal of the old belt without damaging any components.

Align New Belt Properly:

Carefully match the grooves on your new belt with the pulley ribs as per the routing diagram.

Follow the Diagram Sequence:

Route the belt in the order shown on your Toyota Hiace engine belt diagram. A common sequence is:Crankshaft → Water Pump → Alternator → AC Compressor.

Secure with Correct Torque:

Once in place, tighten the tensioner bolt to approximately 40 Nm to ensure the belt is securely fastened.

Common Belt Diagram Misinterpretations

Frequent Errors to Avoid

Using the diagram incorrectly can lead to serious engine issues. Here are some common mistakes:

Mistake | Consequence |

|---|---|

Reversing the pulley routing | May result in battery drain or energy loss within two weeks |

Over-tightening the belt | Can cause premature bearing failure and undue strain |

Ignoring alignment marks | May lead to belt slippage or ineffective power transmission |

When to Consult Professionals

If you encounter any uncertainties during the belt replacement, consider seeking professional help if:

The symbols and markings on your belt diagram appear faded or worn out.

You notice unusual high-pitched squeals after the installation.

The vehicle has experienced deep water exposure, raising concerns about component integrity.

Maintaining Your 2025 Hiace Belt System

Monthly Check Routine

A regular checkup can extend the life of your belt system. Here’s how you can manage a monthly routine:

Perform a visual inspection for any cracks. If you notice a crack deeper than 3mm, it is time to replace the belt.

Use a belt tension gauge to verify that there is a 12-15mm deflection at the midpoint when pressed.

Clean the pulley surfaces with isopropyl alcohol to remove any accumulated grime that might affect belt performance.

Climate Considerations

In regions such as the UAE or other parts of the GCC where summer temperatures can soar beyond 45°C, heat can accelerate belt deterioration. You might consider:

Scheduling inspections every 6 months to detect early signs of wear.

Investing in OEM-approved heat-resistant belts suitable for extreme conditions.

Parking your vehicle in shaded or garage areas during peak sunlight hours to reduce thermal stress.

FAQ

Q1:How often should I inspect and replace my Toyota Hiace engine belt?

Regular inspections should be carried out every month to check for visual signs of wear like cracks or fraying. The drive (V-ribbed) belt typically needs replacement every 60,000 km, while the timing belt, if equipped, should be replaced every 100,000 km. Frequent checks help prevent unexpected breakdowns, especially in the hot climates typical of the GCC region. Maintaining adherence to the engine belt diagram can ensure that you are following manufacturer recommendations, keeping your engine reliable and efficient.

Q2:What are the key indicators that point to a failing belt?

Look for any wear patterns such as cracks, glazing, or misalignment in the belt. Unusual noises, particularly a high-pitched squeal, can also indicate that the belt or tensioner pulley is failing. Moreover, if you observe that the belt is slipping or losing its grip on the pulleys, it might be time for a replacement. Using the Toyota Hiace engine belt diagram as your guide ensures that if any sign is detected, you can quickly identify the source and address it.

Q3:How important is it to follow the belt routing diagram accurately?

The belt routing diagram is a critical tool that demonstrates the correct order and alignment of all pulleys and components involved in the belt system. Skipping or misinterpreting a step can lead to issues like battery drain, bearing failure, or engine overheating. Following the diagram ensures that every accessory receives proper power and that the belt tension is maintained correctly. This precision is essential, particularly for those looking to perform a successful serpentine belt replacement without stressful surprises.

Q4:Can extreme heat affect the performance of my engine belt?

Yes, extreme heat, which is common in the GCC region, can cause premature aging and wear of the engine belt. Elevated temperatures may lead to the belt losing its elasticity and can cause faster deterioration of the material. Regular maintenance and the use of heat-resistant belts recommended by Toyota can help mitigate these effects. Ensuring proper tension and calibration with the diagram will also help you manage heat-related issues effectively.

This article is for reference only. Please refer to local laws and regulations for the latest guidelines.

Read More:

What Is O/D in Car? 2025's Essential Guide to Smarter Driving

How to Transfer Car Ownership in Saudi Arabia Through Absher (2025 Guide)

3 pics

Mustafa Karim, having been deeply involved in automotive research and development for over ten years. He is fond of Japanese cars, and their precise and energy-efficient features have influenced him. In his spare time, he loves Japanese anime and kendo, drawing inspiration from them for control system research and development. He also often shares cutting-edge automotive knowledge on platforms, contributing to industry innovation and adding strength to automotive development with his expertise.